Shandong anyimate Instrument Co., Ltd

Tel: 0531-88092218

400 Tel: 400-9933-057

Mobile: 13356663110

Address: building 105, building 155, Xinmao Qilu science and Technology City, 299 Zidong Avenue, Tianqiao District, Jinan City, Shandong Province

Product Introduction:

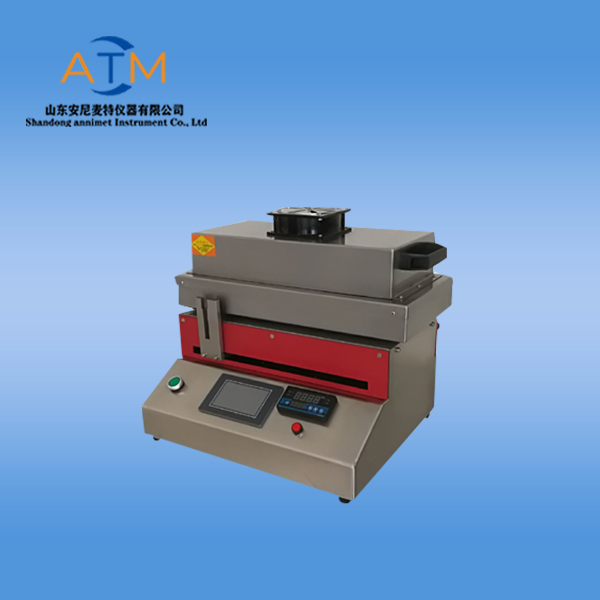

The AT-TB-2000 series coating testing machine is meticulously developed by Shandong Annimat Instrument Co., Ltd. It is used for coating sample testing on materials such as coatings, adhesives, hot melt adhesives, conductive materials, nanomaterials, etc. on paper, non-woven fabrics, glass, copper foil, aluminum foil, etc.

Due to the main factors affecting the coating, such as coating speed and pressure applied to the applicator, manually applied coatings often exhibit inconsistencies, especially the differences between different individuals, which makes it difficult to compare test results between samples. This coating testing machine is automatically coated, with adjustable coating speed and adjustable coating pressure quantification. Thus fundamentally solving the drawbacks of manual coating. A wet film with good repeatability and accurate coating thickness can be applied. This provides a stable coating sample for the measurement and research of various indicators of the coating.

Technical parameters:

1. Machine type: Flat panel type

2. Coating method: Adjustable scraper B/Four sided scraper C/Wire rod A (various coating methods are optional)

3. Coating speed: Standard type 1-2000mm/min can be set arbitrarily, while high-speed type 1-7000mm/min can be adjusted

4. Effective coating size: 200 x 300mm;

5. System: Ani Detection and Testing Control System V1.0

6. Sample clamping method: mechanical clamp/non-woven fabric fixture/vacuum adsorption optional

7. Compression method: Vertical compression with weights

8. Control method: Touch screen

9. Platform material: Grinding tool steel

10. Platform processing: quenching treatment+mirror polishing+chemical plating

11. Platform flatness: ± 2.5 microns (effective width within 200mm, effective length within 300mm, heating temperature within 200 degrees)

12. Shell material: Overall 304 stainless steel

13. Transmission system: double slide+ball screw

14. External dimensions: 450X280X400mm

15. Power supply for the host: 220V/50Hz, power 180W

Scraping method parameters

Wire rod

1. Structural form: extrusion integrated type

2. Material: Stainless steel material

3. Thickness range: 1.5-200um, one specification per wire rod, machine standard with one wire rod

4. Brand: Japan

Adjustable scraper

1. Thickness: 20-3000um (other thicknesses can be customized)

2. Scraper material: imported stainless steel

3. Scraper connection seat: 2-in-1 multifunctional connection seat

4. Scraper movement mode: direct push

5. Display method: digital display

6. Adjustment accuracy: 0.001mm

7. Scraper straightness: ± 0.0015mm (within 200mm length range)

8. Connection method between scraper and base: split type

Equipment heating form and parameters

Upper heating code 1101

1. Heating method: infrared+hot air (UV curing optional)

2. Heating temperature range: Room temperature -150 degrees Celsius can be set

3. Temperature accuracy: Display accuracy 1 degree Uniformity ≤ 4 degrees

4. Power: 2000W

5. Air volume: adjustable

6. Shell material: stainless steel

Bottom plate heating 1102

1. Heating method: Integrated heating plate

2. Heating temperature range: room temperature -200 degrees Celsius can be set

3. Temperature accuracy: Display accuracy 1 degree Uniformity ≤ 3 degrees

4. Power: 2000W

Substrate loading method and platform parameters

Mechanical clip code 1100

1. Usage: Used to support substrates with certain stress and low elasticity, such as paper, glass, etc

2. Material: Stainless steel

Non woven fabric fixture code 1110

1. Usage: Used to support elastic materials such as textiles, non-woven fabrics, and paper

2. Material: Fine ground quenched round rod

3. Pressure: adjustable (by adjusting the tightness of the screws)

Vacuum adsorption code 1120

1. Usage: Used to support substrates that cannot be self flattened and hard materials for easy access and placement, such as copper foil, aluminum foil, plastic sheets, glass

2. Material: Mold steel quenching treatment+mirror polishing+chemical plating

3. Vacuum adsorption pore size: 0.45mm

4. Number of vacuum adsorption pores: 638

5. Platform flatness: ± 2.5 microns (effective width within 200mm, effective length within 300mm, heating temperature within 200 degrees)

6. Vacuum pump: External water circulation vacuum pump

7. Power supply: 150-220V 50Hz 380W

Magnetic suction support code 1130

1. Usage: Used for adsorbing metal plates with a magnetic suction of 3mm or less

2. Material: Strong magnetic platform

3. Table surface flatness: ≤ 3um

Reminder: The flatness error of the flat plate and the straightness error of the scraper do not represent the error of the wet film coating, because the viscosity of the coating and the diameter of the coating particles will affect the coating accuracy during the coating process. At the same time, the fluidity repair of the coating and the forming percentage of the wet dry film will reduce machine errors

Product features:

1. Adopting ball screw transmission for better smoothness of operation

2. The speed is digitally adjustable and can be selected according to needs

3. Pressure: The pressure value is quantified using a weight pressurization structure, making it convenient to adjust the pressure

4. The platform has undergone special process treatment, resulting in good flatness, which is more than 10 times higher than the flatness of glass

5. Equipped with a vacuum adsorption plate, it can adsorb substrates with surface flatness and certain stress. The external vacuum pump can reduce the impact of vacuum vibration on coating.

6. The bottom plate adopts a special treatment process that does not deform when heated within a certain temperature range, fully ensuring the uniformity of coating.

Optional functions and application scope of coating testing machine:

1. Bottom plate heating function: Used for coating liquids that require fluidity at a certain temperature, and a certain temperature must always be maintained during the coating process. Applicable materials: hot melt adhesive, adhesive, etc

2. Upper heating: Dry the sample directly on the machine, and the low viscosity of the coating liquid can easily cause changes in coating thickness during movement. Applicable material: Lithium battery electrode coating.

3. Vacuum adsorption plate: used to fix materials with certain stress that cannot be flattened by their own gravity. Applicable materials: copper foil, aluminum foil, glass plate, and plastic sheets with relatively high thickness.

Selection of coating wire rods and scrapers

For coating tests with high viscosity and high coating thickness, a four sided scraper or adjustable scraper is generally used for coating.

For coating tests with low viscosity and thin coating thickness, wire rod coating is generally used.

After sales service:

Thank you for your inquiry. Shandong Annimat Instrument Co., Ltd. was established in 2007 and has been committed to the research, development, production, and sales of quality testing instruments for nearly a decade. In the production and operation process, product quality is regarded as the life of the enterprise, and every product developed by the company is constantly improved, striving for perfection. Throughout the history of human technological development, we firmly believe that the birth of any product depends on the development of technology, and the development of any technology originates from the exploration of materials. The exploration of any material depends on the progress of technology, and the progress of any technology is supported by experimental means. Humans never lack ideas, and we need the means to realize them. Annimat Instruments will continue to provide means for your ideas and creativity. If you have any questions, please feel free to contact our customer service personnel. We will do our best to provide you with pre-sales, in sales, and after-sales services.